Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

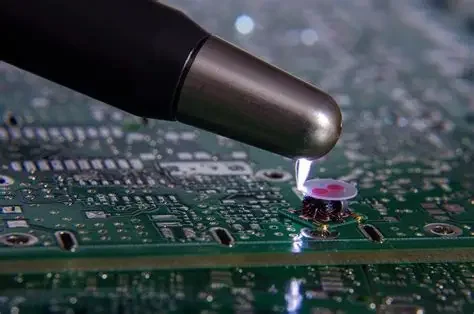

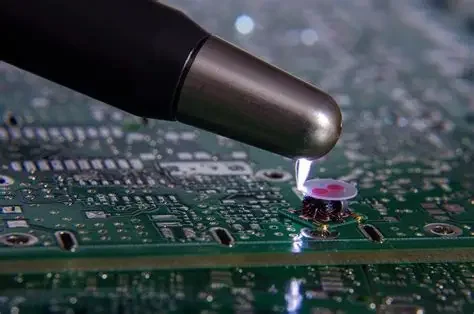

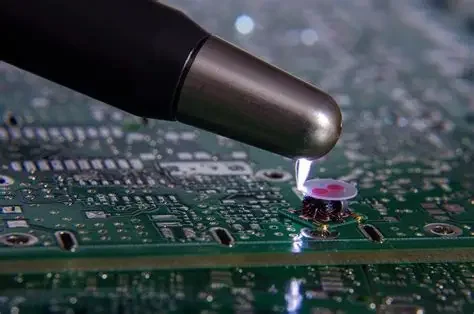

ESD Testing

⚡ ESD Testing Services

Protecting Electronics from Electrostatic Hazards

What Is ESD Testing?

Electrostatic Discharge (ESD) testing evaluates how electronic devices respond to sudden, high-voltage discharges caused by static electricity. These discharges can occur when a person touches a device or when two charged objects come into contact. ESD can damage sensitive components, corrupt data, or cause latent failures that may not appear until long after deployment.

At Faraday Test Lab, we simulate real-world ESD events to ensure your products meet international standards and perform reliably in the field.

Why ESD Testing Matters

✅ Prevents damage to sensitive electronics

✅ Ensures compliance with global EMC standards

✅ Reduces warranty claims and field failures

✅ Enhances product reliability and customer satisfaction

How We Perform ESD Testing

Our lab uses advanced equipment and controlled environments to deliver precise, repeatable results.

Test Setup Includes:

Device placed on an insulating support over a ground reference plane

Controlled temperature and humidity

Discharges applied using an ESD simulator (gun)

Discharge Methods:

Contact Discharge: Direct application to the device

Air Discharge: Discharge through air gap to simulate spark events

Test Points:

External surfaces (metal/plastic)

Connectors and ports (USB, HDMI, Ethernet)

Touchscreens, buttons, and user-accessible areas

Standards We Test To

We follow globally recognized standards to ensure your product meets industry expectations:

IEC 61000-4-2 (most widely used)

Contact: ±2 kV to ±8 kV

Air: ±2 kV to ±15 kV

MIL-STD-883 – Military and aerospace applications

ANSI/ESDA/JEDEC JS-001 – Component-level testing

ISO 10605 – Automotive-specific ESD testing

Equipment Used

ESD Simulator (Gun)

Ground Reference Plane

Insulating Table

Monitoring Equipment (Oscilloscope, Failure Detection Tools)

What We Evaluate

Functional performance during and after discharge

Data integrity (no resets, crashes, or corruption)

Physical damage to components or enclosures

Recovery behavior (automatic reboot or manual reset)

Industries We Serve

🚗 Automotive (ECUs, infotainment, sensors)

📱 Consumer Electronics (phones, tablets, wearables)

🏥 Medical Devices (diagnostic tools, monitors)

🏭 Industrial Controls (PLCs, HMIs, sensors)

✈️ Aerospace & Defense (avionics, communication systems)

⚡ ESD Testing Services

Protecting Electronics from Electrostatic Hazards

What Is ESD Testing?

Electrostatic Discharge (ESD) testing evaluates how electronic devices respond to sudden, high-voltage discharges caused by static electricity. These discharges can occur when a person touches a device or when two charged objects come into contact. ESD can damage sensitive components, corrupt data, or cause latent failures that may not appear until long after deployment.

At Faraday Test Lab, we simulate real-world ESD events to ensure your products meet international standards and perform reliably in the field.

Why ESD Testing Matters

✅ Prevents damage to sensitive electronics

✅ Ensures compliance with global EMC standards

✅ Reduces warranty claims and field failures

✅ Enhances product reliability and customer satisfaction

How We Perform ESD Testing

Our lab uses advanced equipment and controlled environments to deliver precise, repeatable results.

Test Setup Includes:

Device placed on an insulating support over a ground reference plane

Controlled temperature and humidity

Discharges applied using an ESD simulator (gun)

Discharge Methods:

Contact Discharge: Direct application to the device

Air Discharge: Discharge through air gap to simulate spark events

Test Points:

External surfaces (metal/plastic)

Connectors and ports (USB, HDMI, Ethernet)

Touchscreens, buttons, and user-accessible areas

Standards We Test To

We follow globally recognized standards to ensure your product meets industry expectations:

IEC 61000-4-2 (most widely used)

Contact: ±2 kV to ±8 kV

Air: ±2 kV to ±15 kV

MIL-STD-883 – Military and aerospace applications

ANSI/ESDA/JEDEC JS-001 – Component-level testing

ISO 10605 – Automotive-specific ESD testing

Equipment Used

ESD Simulator (Gun)

Ground Reference Plane

Insulating Table

Monitoring Equipment (Oscilloscope, Failure Detection Tools)

What We Evaluate

Functional performance during and after discharge

Data integrity (no resets, crashes, or corruption)

Physical damage to components or enclosures

Recovery behavior (automatic reboot or manual reset)

Industries We Serve

🚗 Automotive (ECUs, infotainment, sensors)

📱 Consumer Electronics (phones, tablets, wearables)

🏥 Medical Devices (diagnostic tools, monitors)

🏭 Industrial Controls (PLCs, HMIs, sensors)

✈️ Aerospace & Defense (avionics, communication systems)