Comprehensive EMC Testing & Engineering Services

Comprehensive EMC Testing & Engineering Services

Full-Spectrum EMC Testing & Engineering Solutions

At Faraday Test Lab, we deliver advanced EMC testing and engineering services designed to support every phase of your product development cycle—from concept to certification.

Whether you're launching a new product or refining an existing design, our team provides the technical insight and testing precision needed to meet global compliance standards efficiently and cost-effectively.

Our Core Services Include:

Radiated & Conducted Emissions Testing

Ensure your product meets regulatory limits for electromagnetic emissions across a wide range of frequencies and environments.Immunity Testing

Evaluate your product’s resilience to external electromagnetic disturbances, including RF fields, EFT, surge, and more.Electrostatic Discharge (ESD) Testing

Simulate real-world ESD events to verify your product’s robustness and compliance with industry standards.Pre-Compliance Evaluations

Identify and resolve potential EMC issues early in the design process to reduce costly delays and redesigns.Custom Test Plans & Engineering Support

Collaborate with our engineers to develop tailored test strategies that align with your product’s unique requirements and target markets.Design Reviews & Troubleshooting

Gain expert feedback on PCB layout, shielding, grounding, and cable routing to improve EMC performance before testing begins.Regulatory Guidance & Certification Support

Navigate complex international standards (FCC, CE, CISPR, ISO, MIL-STD, etc.) with confidence, backed by our technical expertise.

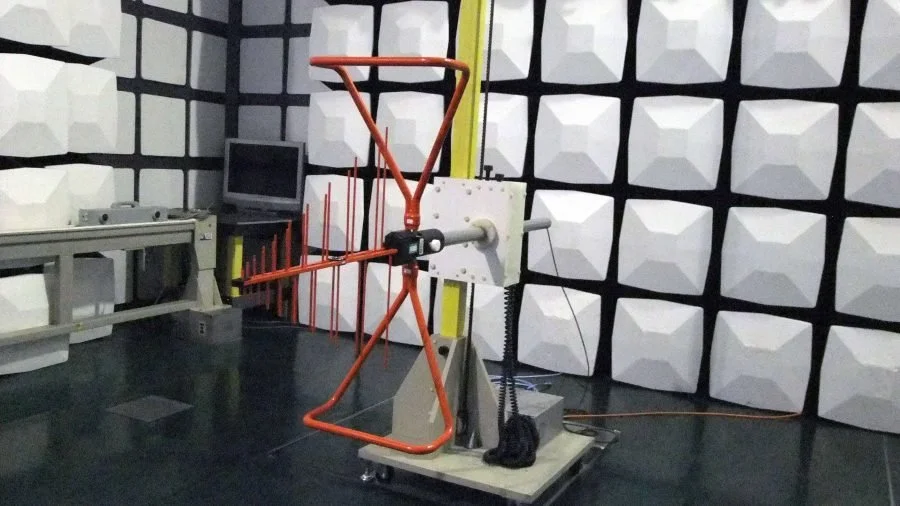

Advanced EMC Testing Services at Faraday Test Labs

We deliver a full suite of world-class electromagnetic compatibility (EMC) testing services designed to ensure your products meet or exceed global regulatory requirements and industry standards.

Engineering & Testing Support Services

At Faraday Test Lab, we provide comprehensive engineering and testing support services designed to guide your product through every phase of the EMC compliance lifecycle—from early-stage planning and design reviews to final certification and post-test troubleshooting. Our approach is rooted in technical excellence, regulatory insight, and a commitment to helping clients bring safe, compliant, and high-performing products to market efficiently.

We understand that EMC testing is not just a regulatory checkbox—it’s a critical part of product development that impacts performance, reliability, safety, and marketability. That’s why our services are built to support your team with customized solutions, responsive communication, and deep technical expertise.

🔍 Technical Consultation

Our team of experienced EMC engineers works closely with clients to develop tailored testing strategies that align with product design goals, industry standards, and global regulatory requirements. Whether you're launching a new product or entering a new market, we help you navigate the complex landscape of EMC compliance with clarity and confidence.

We provide:

Pre-test design reviews to identify potential EMC risks early

Guidance on applicable standards (FCC, CE, CISPR, ISO, MIL-STD, etc.)

Strategic planning for multi-phase testing and certification

Support for integrating EMC considerations into your product lifecycle

📅 Test Processing & Coordination

Efficient project management is essential to keeping your development timeline on track. At Faraday Test Lab, we offer end-to-end coordination of your EMC testing program, ensuring that every phase is executed smoothly and on schedule.

Our coordination services include:

Flexible scheduling to accommodate your project needs

Real-time updates and communication throughout the testing process

Coordination of internal and external resources, including subcontracted services

Documentation management and delivery of test reports in a timely manner

We understand that delays in testing can lead to missed launch dates and increased costs. That’s why we prioritize responsiveness, transparency, and proactive planning in every engagement.

🧪 Custom Test Solutions

No two products are exactly alike—and neither are their EMC challenges. Our lab specializes in developing custom test setups and methodologies to address unique product configurations, non-standard requirements, and complex testing scenarios.

We support:

Specialized fixtures and harnesses

Custom software or firmware integration for test automation

Non-standard test environments or conditions

Hybrid testing approaches for multi-functional devices

Our engineers work collaboratively with your team to ensure that custom solutions are technically sound, repeatable, and fully documented for compliance and traceability.

📝 Test Plan Development & Authoring

A well-structured test plan is the foundation of a successful EMC evaluation. We offer comprehensive test plan development and authoring services, ensuring that your testing is aligned with both regulatory expectations and your internal quality standards.

Our test plans include:

Detailed test procedures and configurations

References to applicable standards and clauses

Acceptance criteria and measurement tolerances

Equipment lists and calibration traceability

Risk assessments and contingency planning

Whether you need a test plan for internal validation, third-party certification, or customer submission, we ensure it is clear, compliant, and audit-ready.

🔍 Failure Analysis & Problem Solving

When EMC issues arise, time is of the essence. Our team provides rapid diagnostics and root-cause analysis to help you identify and resolve problems that could delay your product launch or compromise performance.

Our failure analysis services include:

Real-time troubleshooting during testing

Spectrum analysis and signal tracing

PCB layout and shielding reviews

Grounding and cable routing optimization

Recommendations for design modifications or mitigation techniques

We don’t just identify problems—we help you solve them. Our goal is to get your product back on track with minimal disruption and maximum insight.

🌐 Why Choose Faraday Test Lab?

As an independent, engineer-led laboratory, Faraday Test Lab offers a level of flexibility, focus, and technical depth that sets us apart from larger, generalized test houses. We are currently pursuing ISO/IEC 17025:2017 accreditation through Perry Johnson Laboratory Accreditation, Inc. (PJLA), reinforcing our commitment to quality, traceability, and global compliance standards.

What makes us different:

Personalized service from experienced engineers

Transparent communication and fast turnaround times

Custom solutions for complex or non-standard products

A collaborative approach that treats your success as our own

We serve clients across the automotive, aerospace, medical, industrial, and consumer electronics sectors, providing EMC testing that is not only compliant—but also strategic, efficient, and value-driven.

Specialized Testing & Training Services

Faraday Test Labs offers comprehensive support and advanced testing capabilities to ensure your products meet the highest EMC standards across emerging technologies and complex systems.

Our Key Offerings Include:

Training & Technical Support

Customized training programs and ongoing technical support to empower your team with the knowledge and skills needed for successful EMC compliance.Telematics EMC Testing

Specialized testing for telematics systems, ensuring reliable performance and compliance in connected vehicle environments.EMC Testing Tools & Instrumentation

Utilization and calibration of state-of-the-art EMC testing equipment to guarantee precise and repeatable test results.Hardware-in-the-Loop (HIL) Testing

Real-time simulation and validation of embedded systems under EMC conditions, integrating hardware and software for comprehensive testing.Infotainment System Testing

Thorough EMC evaluation of automotive infotainment and multimedia systems to ensure seamless operation free from electromagnetic interference.

Specialized Testing & Training Services

Faraday Test Labs offers comprehensive support and advanced testing capabilities to ensure your products meet the highest EMC standards across emerging technologies and complex systems.

Our Key Offerings Include:

Training & Technical Support

Customized training programs and ongoing technical support to empower your team with the knowledge and skills needed for successful EMC compliance.Telematics EMC Testing

Specialized testing for telematics systems, ensuring reliable performance and compliance in connected vehicle environments.EMC Testing Tools & Instrumentation

Utilization and calibration of state-of-the-art EMC testing equipment to guarantee precise and repeatable test results.Hardware-in-the-Loop (HIL) Testing

Real-time simulation and validation of embedded systems under EMC conditions, integrating hardware and software for comprehensive testing.Infotainment System Testing

Thorough EMC evaluation of automotive infotainment and multimedia systems to ensure seamless operation free from electromagnetic interference.

Our Core EMC Testing Capabilities:

Bulk Current Injection (BCI) Testing:

Evaluate the immunity of cables and wiring harnesses against RF disturbances using high-frequency current injection techniques, ensuring robust system performance in harsh electromagnetic environments.Conducted Immunity Testing (CI):

Assess your product’s resilience to electromagnetic interference conducted through power or signal lines, per IEC 61000-4-6 and automotive OEM standards.Conducted Emissions Testing (CE):

Measure and control unwanted electromagnetic emissions conducted along cables to ensure compliance with CISPR 25, CISPR 22/32, and FCC Part 15 standards.Radiated Immunity Testing (RI):

Test product susceptibility to external radiated electromagnetic fields, following IEC 61000-4-3, ISO 11452 series, and automotive OEM protocols.Radiated Emissions Testing (RE):

Characterize and mitigate electromagnetic emissions radiated from your product, ensuring compliance with CISPR 25, CISPR 32, FCC, and other regional standards.Electrostatic Discharge (ESD) Testing:

Validate product immunity to ESD events, replicating real-world static discharges using human body model (HBM) and IEC 61000-4-2 test methods.Electrical Fast Transient (EFT) Testing:

Verify product resilience to fast transient bursts caused by switching disturbances on power or signal lines, following IEC 61000-4-4.Surge Immunity Testing:

Simulate high-energy surges typically caused by lightning or switching events, ensuring product durability under transient overvoltage conditions.Power Frequency Magnetic Field Immunity:

Assess product immunity to low-frequency magnetic fields, often required for industrial and automotive applications.Harmonics and Flicker Testing:

Measure harmonic currents and voltage fluctuations to ensure power quality compliance, adhering to IEC 61000-3-2 and IEC 61000-3-3 standards.